10 Business Improvement Techniques That Actually Work

by

- What Are Business Improvement Techniques?

- Why These Techniques Matter for Growing Businesses

- Technique 1: Business Process Management (BPM)

- Technique 2: Continuous Improvement

- Technique 3: Lean Methodology

- Technique 4: Total Quality Management (TQM)

- Technique 5: Business Process Improvement (BPI)

- Technique 6: Process Mapping

- Technique 7: KPIs and Performance Metrics

- Technique 8: Project Management for Improvement Initiatives

- Technique 9: Data-Driven Decision Making

- Technique 10: Employee Engagement and Culture

- Benefits Table: Who Gains What?

- How to Choose the Right Improvement Technique

- Conclusion

- FAQs

Here’s the truth. Every growing business hits a point where the old way of doing things stops working. Maybe tasks take longer than they should, or you notice your team is working hard but still running into the same problems. We have all been there, and it can feel frustrating when you know your team is capable of more, but the system around them is getting in the way.

These are practical approaches you can use to build processes that support your team. Whether you want to clean up one messy workflow or strengthen the foundation of how your whole operation runs, there is something here you can put to use today.

What Are Business Improvement Techniques?

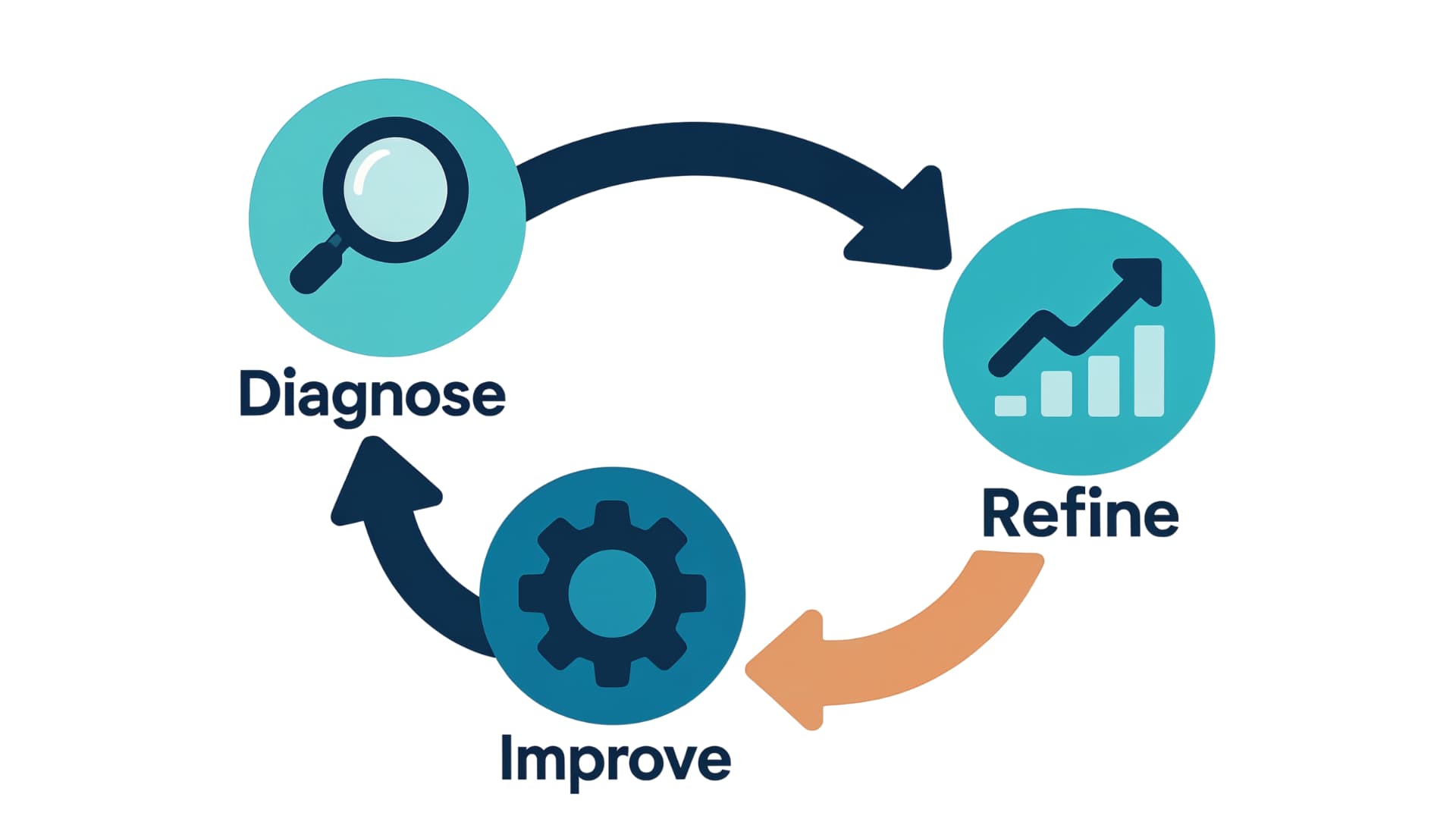

If you have ever felt like your team is working hard but still running in circles, you are not alone. Business improvement techniques give you a structured way to diagnose problems, refine workflows, and create systems that actually make work easier. These techniques are used across industries because they simplify complex operations and make everyday decisions more straightforward.

At a high level, they focus on:

- Making processes more efficient

- Reducing unnecessary work and confusion

- Improving the customer experience

- Helping teams collaborate more smoothly

They turn improvement from an overwhelming idea into a step-by-step practice you can apply consistently.

Why These Techniques Matter for Growing Businesses

Growth is exciting, but it also exposes every gap in your internal systems. Tasks take longer. Handoffs get messy. Communication becomes more complicated to manage. Without a clear approach to improvement, teams often rely on patchwork fixes that don’t hold up.

These techniques help you:

- Identify what is slowing the team down

- Create shared expectations across roles

- Build processes that support long-term scale

- Reduce stress and unnecessary rework

Common benefits include:

- Lower operational costs

- Better customer experiences

- Fewer recurring mistakes

- Stronger team accountability

- Clear, repeatable systems

Most importantly, they give your team the confidence to solve problems proactively rather than react under pressure.

Let Us Help You Get Started!

Pulse CRM delivers more than software. We’re your partner in success.

We fully set up your CRM, including importing your data, configuring sales and marketing automations, designing branded email templates, writing engaging email copy, setting up sales pipelines, and much more.

Technique 1: Business Process Management (BPM)

BPM is one of the most useful ways to understand how work actually happens inside your business. When you map out the whole workflow, you often uncover steps that no one realized were causing delays or confusion. It’s similar to turning the lights on in a room you have been walking through in the dark. Suddenly, everyone can see what needs to change.

BPM usually starts with identifying the processes that matter most, such as how leads are handled, how customers are onboarded, or how internal requests move between teams. Once you choose a process, you break it down step by step. You look at who is involved, what tools are used, where information flows, and where decisions are made.

To make the review more practical, ask questions like:

- Where does this process slow down?

- Which steps rely on memory or tribal knowledge?

- Where does information get lost or repeated?

- What work could be automated if the process were cleaner?

According to a Harvard Business Review study, teams that regularly map and refine core workflows see measurable gains in speed and accuracy. This matches what many growing teams experience. Once a process is documented and simplified, everyone feels more confident, and new hires ramp up faster because they are learning from one clear system rather than multiple unofficial versions.

If you plan to automate parts of a workflow or improve how leads move through a sales pipeline, BPM gives you the clarity you need before making changes. Clean processes make every improvement more effective.

Technique 2: Continuous Improvement

Continuous improvement is about making steady progress rather than relying on big, dramatic changes. Think of it as building a habit of noticing small opportunities instead of waiting until problems spiral into major issues.

Most teams use a simple cycle: Plan, Do, Check, Act. You choose something small to improve, test a new approach, review the results, and adjust. This process keeps improvement from feeling overwhelming and encourages the team to stay curious.

Some practical examples include:

- Simplifying a confusing template

- Adding a checklist to reduce repeated mistakes

- Testing faster follow-up steps in a sales pipeline

- Reducing the number of approvals for routine work

These may seem small at first, but the gains compound quickly. According to the Harvard Business Review, organizations that adopt minor, continuous adjustments often outperform those that chase big, infrequent initiatives. The reason is simple. Small changes are easier to implement, measure, and adopt by teams.

Start with improvements that make daily work easier, and the positive momentum will build naturally.

Technique 3: Lean Methodology

Lean methodology helps you identify the work that adds value and eliminate everything that doesn’t. Many teams don’t realize how much time is lost to unnecessary steps or unclear handoffs until they take a closer look.

Common forms of waste include:

- Long wait times

- Excess movement or repeated steps

- Overprocessing

- Unclear or unnecessary approvals

- Work that doesn’t benefit the customer

A helpful starting point is mapping a workflow and identifying where time or effort is being lost. Questions like these help:

- Are we doing extra work to compensate for unclear steps?

- Where does information get delayed or duplicated?

- Which steps exist out of habit rather than usefulness?

Real-world improvements often look simple. A team might shorten its approval chain, create a shared folder for frequently used assets, or streamline data entry to avoid double work. These small shifts have an outsized impact because they remove friction from everyday tasks.

Lean is most effective when practiced consistently. Once your team understands how to identify waste, they begin spotting opportunities they can improve.

Technique 4: Total Quality Management (TQM)

TQM is built around shared ownership. When everyone feels responsible for quality, the team catches issues earlier and solves them with less friction. Quality becomes a mindset rather than a box to check.

You can apply TQM in practical ways by:

- Reviewing a small set of quality indicators weekly

- Making feedback easy to share and respond to

- Improving documentation for clarity

- Using consistent checklists for recurring tasks

These habits work because they keep quality visible instead of reactive. The Harvard Business Review notes that teams that integrate quality into their day-to-day operations often see fewer errors and less rework.

In real-world scenarios, you can see TQM show up when teams simplify task documentation or set standards for communication. This reduces misunderstandings and maintains consistent work across roles.

Over time, TQM helps build a culture where people take pride in their work and feel more connected to the business’s goals.

Technique 5: Business Process Improvement (BPI)

BPI is ideal when you know exactly which workflow is causing frustration. Instead of rebuilding everything, you focus on the key steps that need attention.

The process is straightforward:

- Document the workflow

- Identify the friction points

- Redesign the steps causing the problem

- Test and refine the updates

To make this effective, ask questions such as:

- Where does work consistently get stuck?

- Which steps cause confusion for new team members?

- What tasks feel heavier than they should?

- How often does this process require rework?

According to Statista, teams that apply a structured process improvement approach achieve greater accuracy and faster cycle times because the changes are easier to adopt.

Real examples might include standardizing an intake form, streamlining approval processes, or restructuring how leads move through a sales pipeline. These updates are impactful but straightforward because they target the real source of friction.

BPI works best when the scope is small, the outcome is clear, and the team understands the purpose behind the change.

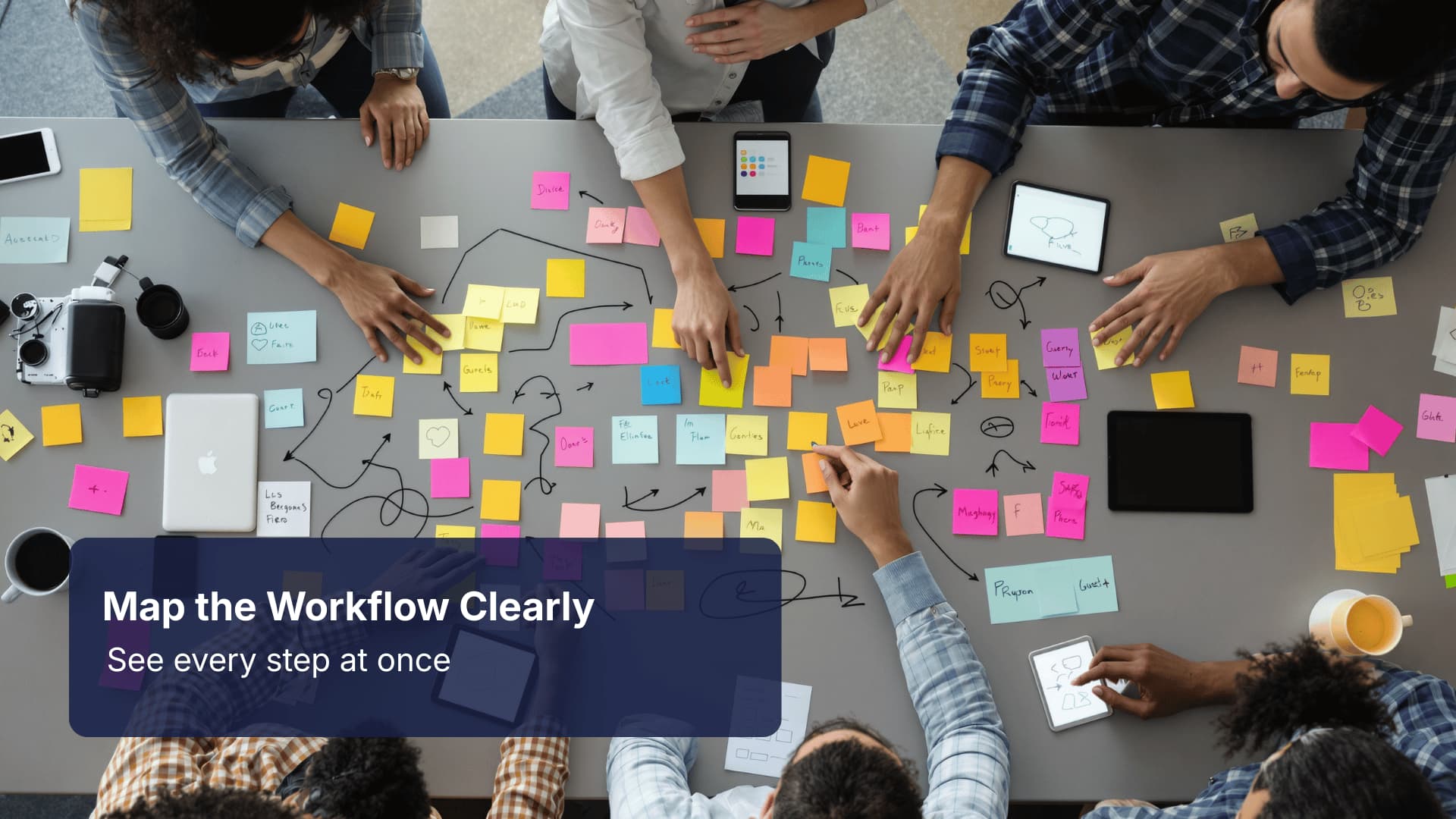

Technique 6: Process Mapping

Process mapping removes the guesswork from improvement. When you see every step laid out, you can finally understand where the workflow breaks down.

A good process map includes:

- Each step from start to finish

- Who owns each piece of work

- What triggers each step

- What tools or information are needed

To make a mapping session productive, ask:

- Where does work wait the longest?

- Which steps depend on manual input?

- Where do new hires typically get stuck?

- Are any steps duplicated or unnecessary?

Process mapping works for almost any department. Support teams map how tickets move from intake to resolution. Sales teams map how leads move through a sales pipeline. Finance teams map how invoices travel through approvals. Each map reveals gaps you can finally address.

Once the process is clear, conversations become more objective. Everyone sees the same picture. Improvements feel collaborative instead of personal.

Technique 7: KPIs and Performance Metrics

KPIs give you a grounded way to understand whether your improvements are working. Without metrics, it is hard to know whether you are fixing the correct problems or assigning energy in the right places. Numbers do not replace judgment, but they add clarity so you can make decisions with more confidence.

Clear KPIs often include:

- Customer response time

- Lead conversion rates

- Revenue per client

- Project cycle time

To make KPIs useful, consider:

- Does this metric connect directly to an important business outcome?

- Can the team realistically influence it?

- Are we reviewing it often enough to catch trends early?

Teams use KPIs differently depending on their goals. Support teams may track first response time to reduce customer frustration. Sales teams can review how long leads remain in each stage of the sales pipeline and identify where prospects lose interest. Product teams may monitor feature adoption to understand what customers value.

The Harvard Business Review notes that companies that use a small set of leading indicators often outperform those that rely on long lists of lagging metrics. Fewer, more meaningful KPIs help teams focus on improvements that create real change rather than chasing numbers that look good but don't alter performance.

KPIs also promote alignment. When everyone sees the same data, it becomes easier to prioritize work, explain decisions, and collaborate on improvements.

When KPIs are reviewed regularly, they become a reliable guide for understanding trends, spotting issues early, and measuring the impact of changes over time.

Technique 8: Project Management for Improvement Initiatives

Project management is what turns ideas into finished improvements. Without structure, even valuable initiatives lose momentum or become too overwhelming to finish. Good project management keeps work organized, expectations clear, and everyone moving in the same direction.

A strong improvement project usually begins with clarity about the desired outcome. You identify the problem, define the goal, and break the work into smaller, manageable steps. Each step is assigned to a person with a clear timeline so nothing sits idle.

These questions help shape a strong project plan:

- What does success look like?

- Who needs to be involved at each stage?

- Where might delays or complications happen?

- How will progress be tracked?

Research from the Project Management Institute shows that a lack of visibility is one of the main causes of project failure. When teams cannot see what is happening or what comes next, even simple improvements can stall. Structured project management solves this by providing a single source of truth for everyone.

Real-world applications are simple. A team may use a shared task board to track each step of a new workflow. A manager may schedule brief weekly check-ins to keep work moving. A department may outline each step required to launch an internal process update and use a checklist to ensure quality.

Project management also helps you understand the impact of your improvements. When tasks are tracked clearly, you can see which changes worked and which ones need refinement.

At its core, project management gives structure to improvement. It helps teams stay focused, reduces confusion, and ensures good ideas turn into tangible results.

Technique 9: Data-Driven Decision Making

Data-driven decision-making gives you a clearer, more objective view of what is happening in your business. Instead of relying on instinct or anecdotal feedback, you use real numbers to understand where work slows down, which activities are paying off, and where hidden opportunities exist. When teams learn to look at data this way, they solve problems earlier and make choices that support long-term growth.

Most teams start by pulling simple data from the tools they already use. Reviewing CRM activity, customer behavior patterns, operational bottlenecks, and sales performance gives you a grounded sense of what is working and where things may be breaking down. You do not need complex dashboards to get started. What matters most is choosing a few meaningful signals and checking them consistently.

To make this practical, teams often ask questions such as:

- Which metrics reflect the actual health of this workflow?

- What behaviors or patterns show up repeatedly across weeks or months?

- Where are we losing time, customers, or opportunities?

- What change can we test based on the numbers?

These questions help convert raw information into actionable insight. According to the Harvard Business Review, organizations that base decisions on consistent, high-quality data tend to outperform their peers because they adapt faster and more accurately. Data removes guesswork, and it gives teams the clarity they need to focus on the correct problems.

Real-world examples vary by team. A customer service department may notice that resolution times spike on certain days and adjust staffing accordingly. A marketing team may review lead sources and discover that one channel generates high traffic but low conversions. A sales group might track movement through a sales pipeline to understand exactly where prospects stall. Each insight points to a practical next step.

To strengthen this approach, start with simple habits. Review your core metrics weekly. Document what changed and why you think it changed. Test one minor adjustment at a time, then measure the impact. These small cycles build confidence and sharpen your ability to interpret data without overreacting.

The real advantage of data-driven decision-making is alignment. When everyone sees the same numbers, and decisions feel fair and grounded. Teams can discuss performance openly, identify improvements together, and move forward with shared understanding. Over time, this creates a culture where decisions are thoughtful, intentional, and tied to results rather than assumptions.

Technique 10: Employee Engagement and Culture

When people feel supported, they speak up earlier and help solve problems before they grow. Engagement turns improvement into a shared habit rather than a top-down directive. You can usually feel the difference in an engaged team. People ask questions sooner, volunteer ideas more freely, and take more ownership of their work.

You can encourage engagement by:

- Welcoming ideas without judgment

- Giving helpful, specific feedback

- Making collaboration a regular part of team routines

- Celebrating wins, even small ones

These practices work because they build trust. When people know their input matters, they are more likely to look for opportunities to improve the work around them.

Real-world examples are often small. A team may run a monthly improvement session to highlight small fixes. A manager may ask for one process improvement idea during each one-on-one. A department may track recurring issues and choose one to solve together each month. These moments build a culture where improvement is normal.

Over time, engagement strengthens accountability and consistency. People feel more connected to the business and more responsible for its success. That energy is what keeps improvement moving even when things get busy.

Let Us Help You Get Started!

Pulse CRM delivers more than software. We’re your partner in success.

We fully set up your CRM, including importing your data, configuring sales and marketing automations, designing branded email templates, writing engaging email copy, setting up sales pipelines, and much more.

Benefits Table: Who Gains What?

| Role | Key Benefit | Why It Matters |

|---|---|---|

|

Leadership |

Better visibility |

Faster decision-making |

|

Operations |

Fewer bottlenecks |

Smoother execution |

|

Sales/Marketing |

Consistent workflows |

Improved customer results |

How to Choose the Right Improvement Technique

When you are deciding where to start, the goal is not to pick the perfect technique. It is to choose the one that gives your team the clearest path forward without overwhelming them. Each improvement method has strengths, so the right choice depends on what you need most right now. A good starting point is to look at your biggest friction points and choose the technique that helps you address them with the least complexity.

Here are the core factors to weigh:

- Your immediate goals, such as reducing delays, improving communication, or tightening quality.

- The size and capacity of your team, since smaller teams often benefit from lighter, focused methods.

- Workflow complexity determines whether you need a complete process review or a targeted fix.

- Your timeline for results, especially if stakeholders expect early wins.

Simple rule of thumb:

- Overwhelmed by chaos → start with process mapping. It provides clarity and quickly uncovers issues.

- Want steady, ongoing growth → choose continuous improvement. It builds helpful habits without disrupting daily work.

- Need a quick fix for a known pain point → try BPI. It targets one workflow and delivers fast results.

If you prefer a more structured approach, consider these guiding questions:

- Do we fully understand how this workflow operates today?

- Can we isolate the issue to one process, or is this part of a larger pattern?

- Are people frustrated by one recurring friction point, or is the whole system unclear?

- What type of change will create relief the fastest?

For example, if your team constantly loses track of tasks or miscommunicates handoffs, process mapping can reveal exactly where the breakdown occurs. If a particular workflow is slowing down the entire department, BPI lets you focus directly on that process. And if your team is already performing well but wants to get more efficient over time, continuous improvement helps you build a culture around frequent, low-stress refinement.

No single technique is a silver bullet. The most effective teams blend several approaches over time, starting small and expanding as their systems mature.

Conclusion

Improvement is not a single event. It is something your business grows into over time. The more familiar your team becomes with spotting issues, testing ideas, and refining workflows, the easier it becomes to stay organized and move with confidence.

The best way to begin is with one small win. Pick a workflow you use daily, map it out, and look for one step that could be easier. Try a simple change, see how it feels, and adjust as needed. That first improvement builds trust, and each step after becomes a little clearer.

Small steps create lasting change. You focus on the business, and these systems can help you keep it moving forward.

FAQs

Start by mapping the workflow to see how work truly moves from start to finish. Seeing the steps laid out helps you spot delays, repeated actions, or decisions that slow things down. Most teams are surprised by how different the actual process is from what they assumed. Once the map is clear, you can pick one step to simplify or streamline without overwhelming the team.

A quarterly review works well for most businesses, although rapidly growing teams may benefit from checking key workflows monthly. The goal is not to overhaul everything, but to catch issues before they compound. If you notice the same problems resurfacing, that is usually a sign that the workflow needs another look. Regular reviews help you stay ahead of breakdowns instead of reacting to them.

Smaller teams often see the fastest wins with continuous improvement or BPI because the scope is focused and easy to manage. These approaches let you fix one friction point at a time without disrupting the entire system. For example, tightening one handoff or simplifying one approval step can save hours of frustration each month. These smaller wins build confidence and momentum.

Not in the beginning. Most improvements start with clear communication, simple documentation, or a basic workflow map. As your processes mature, tools can help automate tasks, improve task visibility, and generate reports. If you frequently revisit the same problems or need more precise coordination across roles, that is often the right moment to introduce software support.

Minor improvements can make a noticeable difference within one to three weeks, especially when they remove daily friction. Larger process redesigns take longer, but they also solve deeper issues that were slowing the team down. A good way to track progress is to define one metric and watch how it changes after each adjustment. As momentum builds, improvements become easier and more consistent.